Categories

Products

Tower type dry mixed mortar equipment

A professional R&D and design team is a prerequisite for ensuring product quality, and the parts and components supporting the production equipment are purchased globally to ensure the stable operation of the equipment.

Tandem dry mixed mortar production line

A professional R&D and design team is a prerequisite for ensuring product quality, and the parts and components supporting the production equipment are purchased globally to ensure the stable operation of the equipment.

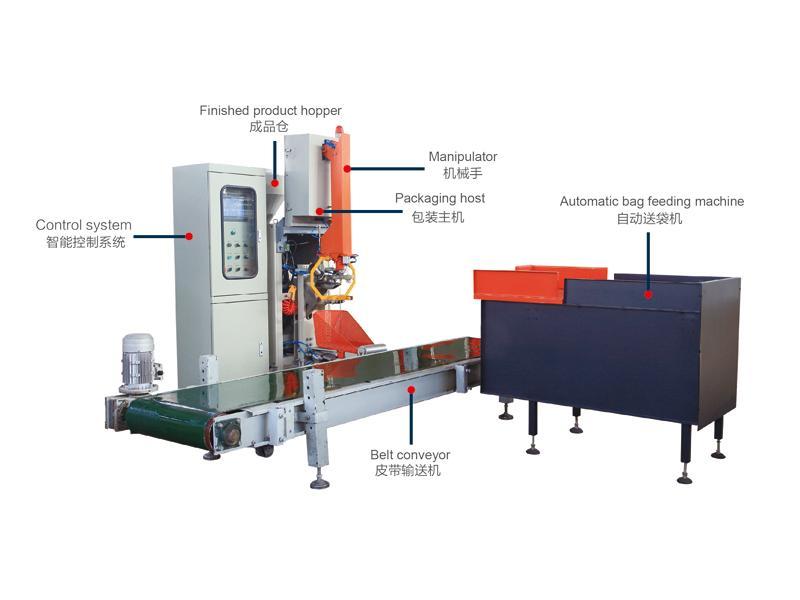

BCSX series intelligent packaging line

The first step is to place the packaging bags in multiple areas of the automatic bag feeder according to the mortar varieties produced by the mortar factory.

Dry free ready mixed mortar complete equipment

Due to a certain amount of stone powder, the workability of premixed mortar can be improved, which is more consistent with the mix proportion of machine sprayed mortar

Series concrete mixing plants are our traditional products. They have specifications such as HLS240, HZS200, HLS150 and HZS120, small combined mixing plants

It has a complete set of automatic bagging and packaging capabilities.Equipped with multi-model packaging machines, different packaging production lines are selected for different materials, and multi-model palletizing lines are configured. It is a generalist of different mortar packaging.

Station type dry mixed mortar production line

A professional R&D and design team is a prerequisite for ensuring product quality, and the parts and components supporting the production equipment are purchased globally to ensure the stable operation of the equipment.

Workshop-type special mortar production line

Reasonable design plan, the aggregate adopts environmentally friendly sand-making floor or three-cylinder dryer, which is energy-saving and low-consumption.Dust collectors installed in different locations can maximize the dust removal of the equipment and effectively ensure the energy-saving and environmentally friendly operation of the equipment.

Workshop-style multi-model mortar production equipment

Reasonable design plan, the aggregate adopts environmentally friendly sand-making floor or three-cylinder dryer, which is energy-saving and low-consumption.Dust collectors installed in different locations can maximize the dust removal of the equipment and effectively ensure the energy-saving and environmentally friendly operation of the equipment.

High precision admixture proportioning scale

The high-precision admixture dosing scale is composed of a top dust collector, a stainless steel storage cylinder, a rotating feeding device, a quantitative (or continuous) scale, an intelligent control system, a rack and other components.;